TPS54320RHLR Common troubleshooting and solutions

Sure! Here's a 2000-word article with two parts on the theme " TPS54320RHLR Common Troubleshooting and Solutions."

part 1: Understanding the TPS54320RHLR and Its Common Issues

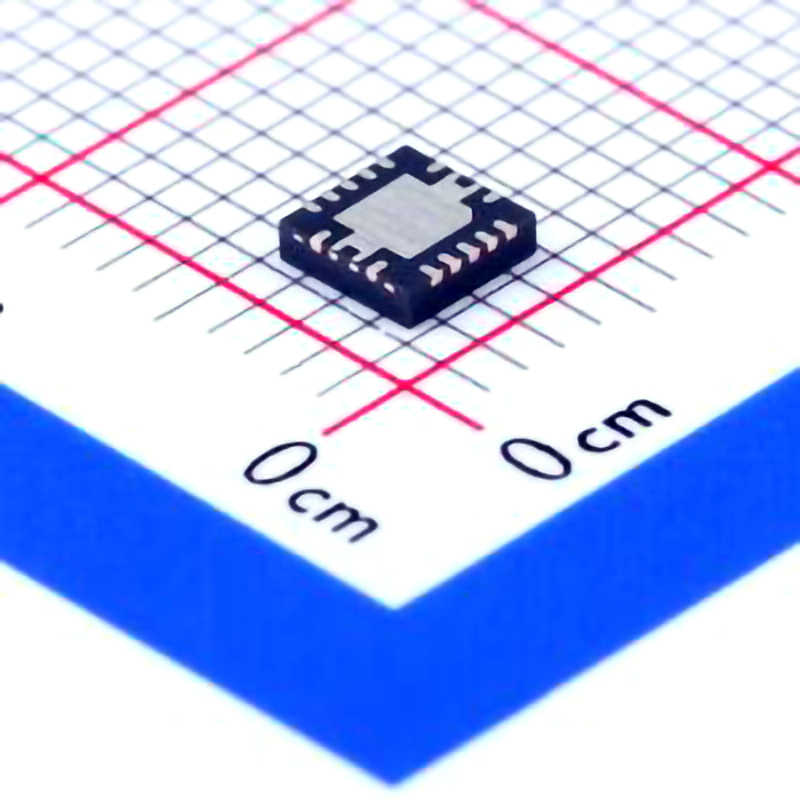

The TPS54320RHLR is a highly efficient, buck converter from Texas Instruments, designed to provide stable voltage regulation with minimal power loss. This component is used in a wide range of applications, from consumer electronics to industrial systems, due to its flexibility, ease of use, and efficient power conversion. However, like any electronic component, the TPS54320RHLR can encounter issues during operation. In this article, we will discuss the most common troubleshooting problems users face and offer practical solutions.

1. Inconsistent Output Voltage

One of the most common issues encountered with the TPS54320RHLR is inconsistent output voltage. The converter is designed to deliver a fixed output voltage, and any deviation from this can be problematic. Inconsistent voltage can lead to improper functioning of the connected circuit, causing instability and inefficiency.

Common Causes:

Incorrect feedback resistor values: The output voltage is determined by the feedback resistors, which set the output voltage ratio. If these resistors are incorrectly selected or are out of tolerance, the output voltage may deviate from the expected value.

Poor PCB layout: A poor layout with inadequate grounding or excessive noise coupling can lead to fluctuations in output voltage. The TPS54320RHLR is sensitive to noise, and a suboptimal layout can cause instability.

Faulty or damaged components: A defective inductor, capacitor , or feedback network can cause the converter to malfunction and produce an unstable output.

Solutions:

Check feedback resistors: Ensure that the resistors are of the correct value and within tolerance. Double-check the schematic to confirm their proper placement.

Revise the PCB layout: A solid ground plane is essential for stable operation. Minimize noise and high-frequency switching interference by placing components carefully and following design guidelines recommended by Texas Instruments.

Test components: Verify that the inductor, capacitors, and feedback network are functioning properly. Use an oscilloscope to monitor the output voltage and identify if there are spikes or fluctuations.

2. Overheating

Overheating is another significant issue that affects the TPS54320RHLR. When the chip or associated components overheat, it can lead to reduced efficiency, potential damage, or failure of the converter.

Common Causes:

Excessive load: If the converter is subjected to a load that exceeds its rated capacity, it will overheat. The TPS54320RHLR is designed for specific output power limits, and exceeding these limits can lead to thermal issues.

Insufficient cooling: A lack of proper heat dissipation due to inadequate heatsinks, poor PCB layout, or insufficient airflow can cause overheating.

Inadequate output capacitance: Insufficient output capacitance can cause a rise in ripple current, leading to additional power dissipation and overheating.

Solutions:

Monitor the load current: Ensure that the current drawn by the load does not exceed the maximum output rating of the TPS54320RHLR. Using an appropriate current-limiting design is essential to prevent overloading.

Improve cooling: Ensure that the TPS54320RHLR has proper heat dissipation. This might involve using thermal vias in the PCB, adding heatsinks, or improving airflow around the converter.

Use adequate output capacitance: Check that the output capacitors are of the correct type and value, as insufficient capacitance can exacerbate thermal problems. Use low-ESR capacitors to minimize ripple current.

3. Unstable Switching Operation

Another issue frequently reported with the TPS54320RHLR is unstable switching operation. This can manifest as a high-frequency noise, erratic switching cycles, or failure to enter a stable switching state.

Common Causes:

Improper component values: The switching frequency of the TPS54320RHLR is determined by external components like the inductor and capacitors. Incorrect component values can cause the converter to operate at an unintended frequency, leading to instability.

Excessive input voltage ripple: High ripple on the input voltage can cause issues with switching operation. The TPS54320RHLR is sensitive to input voltage fluctuations, and any significant ripple can cause the converter to malfunction.

Incorrect or inadequate feedback loop design: The feedback loop is critical in regulating the output voltage. If the feedback network is poorly designed or if there are delays in feedback signals, the converter may fail to stabilize the switching operation.

Solutions:

Check external component values: Ensure that the values of the inductor and capacitors are correctly chosen to match the TPS54320RHLR's requirements. Texas Instruments provides design guidelines to assist in component selection for optimal performance.

Reduce input voltage ripple: Use bulk capacitors or additional filtering stages to reduce input voltage ripple. Ensuring a stable input voltage is key to stable switching operation.

Verify feedback loop stability: Double-check the feedback loop for correct component selection and layout. Ensure that there are no parasitic elements or noise sources that could affect the stability of the loop.

part 2: Advanced Troubleshooting and Preventative Measures for TPS54320RHLR

While the basic issues of inconsistent voltage, overheating, and unstable switching can often be traced back to common causes, more advanced troubleshooting may be necessary for complex systems. In this section, we will explore additional troubleshooting techniques and preventative measures to maintain the TPS54320RHLR’s optimal performance.

4. Noise and EMI Issues

Electromagnetic interference (EMI) and noise are persistent challenges in power electronics. The TPS54320RHLR, like many DC-DC converters, operates at high frequencies, making it susceptible to radiated and conducted EMI. This can affect the surrounding components, circuits, and even other devices in the system.

Common Causes:

High switching frequency: The inherent high-frequency switching of the converter can radiate EMI if not properly contained.

Inadequate shielding and grounding: Poor shielding and grounding can exacerbate EMI problems by allowing noise to propagate through the system.

Improper layout of high-current paths: High-current paths should be minimized and carefully routed to reduce the generation of EMI.

Solutions:

Use proper shielding and filtering: Design the PCB with shielding and use ferrite beads or filters on input/output lines to suppress EMI. Placing the converter within a metal enclosure can also help contain noise.

Improve grounding practices: Implement a solid ground plane to reduce the impact of high-frequency switching noise. Ensure all ground connections are low-resistance to prevent noise coupling.

Minimize high-current paths: Carefully route power traces to minimize loop areas. Avoid running high-current paths close to sensitive analog circuitry.

5. Fault Protection and Recovery

The TPS54320RHLR is equipped with several protection features to prevent damage in case of faults. These include overcurrent protection, thermal shutdown, and under-voltage lockout. Understanding these features and how they can be triggered is essential in diagnosing problems.

Common Causes:

Overcurrent conditions: A fault in the load circuit or excessive current demand can cause the converter to enter overcurrent protection mode, where it shuts down or reduces output to protect itself.

Thermal shutdown: If the converter overheats due to excessive load, inadequate cooling, or poor layout, it will enter thermal shutdown mode to prevent permanent damage.

Under-voltage lockout: If the input voltage falls below a certain threshold, the TPS54320RHLR will not operate to protect itself from insufficient input power.

Solutions:

Monitor current and temperature: Use monitoring circuits to track the load current and temperature of the converter. This can help detect overcurrent or thermal shutdown conditions before they become critical.

Check input voltage: Ensure that the input voltage is stable and above the under-voltage lockout threshold. Any fluctuations in input voltage can lead to erratic behavior and failure to start.

6. Ensuring Long-Term Reliability

To ensure long-term reliability of the TPS54320RHLR in your system, it's crucial to follow best practices during design, component selection, and testing.

Preventative Measures:

Component selection: Use high-quality components that are rated for long-term operation under the expected load and environmental conditions. Ensure that the capacitors and inductors are suitable for high-frequency switching applications.

PCB design considerations: Follow recommended PCB layout guidelines, focusing on minimizing noise and ensuring proper heat dissipation.

Testing under varying conditions: Conduct thorough testing across different temperatures, load conditions, and input voltages. This will help identify potential issues before they affect your system in real-world conditions.

Conclusion

The TPS54320RHLR is a powerful and versatile buck converter, but like any complex electronic component, it requires careful attention to design, operation, and troubleshooting. By understanding common issues such as inconsistent output voltage, overheating, unstable switching, and noise, users can take proactive steps to address these problems. Advanced troubleshooting techniques, including monitoring thermal and current conditions, improving grounding, and ensuring fault protection, can significantly improve the performance and reliability of the converter. By following these guidelines, you can ensure that the TPS54320RHLR operates optimally, delivering reliable power to your system for years to come.

This concludes the 2-part article on troubleshooting and solutions for the TPS54320RHLR. If you need further details or adjustments, feel free to let me know!

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.