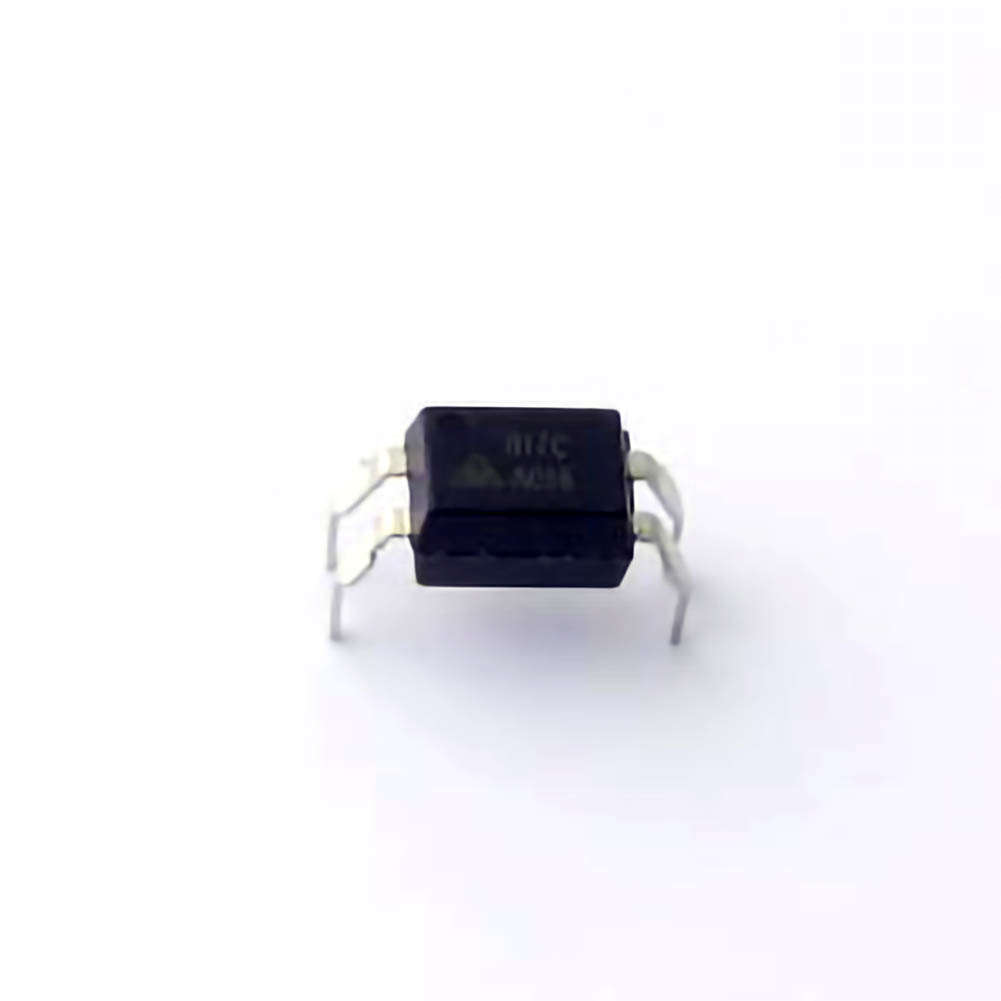

PC817 optocoupler working principle and electrical isolation circuit design

The PC817 Optocoupler is a key component widely used in Electrical isolation circuits. This article explores the working principle of the PC817 , its applications, and the design of circuits that leverage its electrical isolation properties, making it an essential component in modern electronics.

PC817, optocoupler, working principle, electrical isolation, circuit design, isolation circuit, transistor , LED , high voltage protection, noise reduction.

The Working Principle of the PC817 Optocoupler

The PC817 optocoupler, commonly referred to as an optoisolator, plays an essential role in modern electrical systems by providing electrical isolation between different sections of a circuit. This protection is crucial in scenarios where high voltage, noise, or voltage spikes may damage sensitive components. To fully understand the significance of the PC817 and how it operates, we first need to explore its structure and how it works.

1.1 What is an Optocoupler?

An optocoupler is a s EMI conductor device that uses light to transmit signals between two electrically isolated circuits. This isolation is achieved by using an LED (light-emitting diode) and a phototransistor (or photodiode) within the same package. The primary function of an optocoupler like the PC817 is to prevent electrical surges or noise from propagating between circuits, thus ensuring the protection of sensitive components while maintaining signal integrity.

The PC817 optocoupler consists of an LED and a phototransistor. The LED is the input component, and the phototransistor is the output component. When a voltage is applied to the LED, it emits light. The phototransistor detects this light and converts it back into an electrical signal, but the circuits connected to the LED and phototransistor are electrically isolated from each other.

1.2 The Working Mechanism of the PC817

The basic operation of the PC817 relies on the interaction between light and the phototransistor. When a current flows through the LED in the input side, it generates light. The emitted light then strikes the phototransistor on the output side, causing it to conduct. The amount of current passing through the phototransistor is proportional to the intensity of the light received, and this in turn allows the signal to be transferred from the input to the output.

Here’s a step-by-step breakdown of how the PC817 operates:

LED Activation: When an electrical signal is applied to the LED, the LED emits infrared light.

Light Detection: The infrared light is received by the phototransistor, which is optically coupled to the LED.

Signal Transfer: The phototransistor’s base-emitter junction is forward biased due to the light energy, causing the transistor to turn on and conduct current. This allows the input signal to be transferred to the output without any physical electrical connection.

The key advantage of this setup is that the input and output circuits are electrically isolated from each other, protecting sensitive components from high voltage transients or electrical noise.

1.3 Advantages of Using the PC817 Optocoupler

Electrical Isolation: The most significant advantage of using the PC817 is its ability to provide electrical isolation. This prevents high voltages in one section of the circuit from reaching and damaging the other section.

Noise Reduction: The PC817 is effective at reducing electrical noise. This makes it ideal for applications in industrial environments where electromagnetic interference (EMI) and electrical noise are common.

Signal Integrity: The PC817 ensures that the signal integrity is maintained by preventing any disturbances or voltage fluctuations from transferring between circuits.

Safety: The electrical isolation provided by the PC817 enhances the safety of the system, especially in high-voltage environments where there is a risk of electric shock or short circuits.

1.4 Applications of the PC817 Optocoupler

The PC817 is widely used in a range of applications due to its reliability and performance. Some common use cases include:

Microcontroller Interfacing: It is commonly used to interface microcontrollers with high voltage circuits, enabling safe Communication between them.

Switching Power Supplies: In power electronics, PC817 optocouplers provide isolation between the high voltage input side and the low voltage output side of a switching power supply.

Signal Isolation in Communication Systems: PC817 optocouplers are often used to isolate signals between different parts of communication systems, preventing cross-talk and ensuring signal clarity.

Motor Control Circuits: PC817 is used to isolate the control signals from the high current drive signals in motor control systems.

Designing Electrical Isolation Circuits Using the PC817

Now that we understand the working principle of the PC817 optocoupler, we can delve into its application in electrical isolation circuit design. The design of such circuits requires careful consideration of factors such as the input signal voltage, the required output signal characteristics, and the optocoupler’s specifications.

2.1 Basic Electrical Isolation Circuit Design

At its core, an electrical isolation circuit using the PC817 typically consists of a driver circuit on the input side, the PC817 itself, and a load on the output side. The input signal drives the LED within the optocoupler, while the phototransistor on the output side switches the load.

Key components:

Resistor (R1): A current-limiting resistor is placed in series with the LED to protect it from excessive current.

Input signal source: The circuit input, which can be a microcontroller or any other digital or analog signal source.

Load resistor (R2): This resistor is used to ensure that the phototransistor operates within its safe limits.

Power supply: The power source for both the input and output circuits.

2.2 Design Considerations for the PC817 Circuit

Input Signal Level: The input signal to the PC817 must be compatible with the forward voltage of the LED, typically around 1.2V to 1.5V for the PC817. The current through the LED is typically limited by a series resistor (R1), and this value should be chosen based on the desired current through the LED. The input signal should also be able to drive the current through the LED sufficiently to activate the phototransistor.

Load Impedance: The output side of the PC817 typically drives a load that can be either a low-voltage logic input, a transistor, or an op-amp. It is essential to calculate the proper value of the output resistor (R2) to match the load impedance.

Isolation Voltage: One of the most important factors to consider in isolation circuit design is the maximum voltage that can be safely isolated by the PC817. This voltage, known as the “input-to-output isolation voltage,” typically ranges up to 5 kV for the PC817, which makes it ideal for separating low and high voltage sections.

Response Time: The PC817’s switching speed can vary depending on the specific model. It is important to choose the correct optocoupler based on the switching frequency of the application. For high-speed applications, optocouplers with faster response times, such as the PC817, are preferred.

Output Signal Levels: After the signal is optically transmitted through the PC817, it is necessary to convert the phototransistor’s output into the appropriate logic levels or drive signals for the next stage in the circuit.

2.3 Common Circuit Design Examples

Microcontroller Interface Circuit: To interface a microcontroller with a high-voltage system, the microcontroller’s output is connected to the LED side of the PC817, while the phototransistor side drives the high-voltage component. The circuit ensures the microcontroller is protected from high voltages.

Switching Power Supply Isolation: In a switching power supply, the PC817 can be used to isolate the control circuit from the power circuit. The LED side of the PC817 is driven by the control circuitry, while the phototransistor side controls the switching device, such as a MOSFET.

Motor Driver Isolation: In motor control applications, the PC817 provides electrical isolation between the low-voltage logic circuitry and the high-current drive circuitry, ensuring safety and preventing damage to sensitive components.

2.4 Practical Considerations

When designing a circuit using the PC817, it’s essential to consider thermal management, component tolerances, and any potential electromagnetic interference (EMI) that could affect the system. Additionally, the reliability of the circuit is crucial in industrial applications, where long-term performance is essential. Proper testing and validation of the design should be performed to ensure that the optocoupler functions as expected under different operational conditions.

In conclusion, the PC817 optocoupler is a versatile and reliable component that plays a critical role in providing electrical isolation in modern electronic systems. Whether it’s protecting sensitive circuits from high voltage or reducing noise in industrial environments, the PC817 ensures both safety and signal integrity. By understanding its working principle and how to design circuits using this component, engineers can create more robust and reliable systems for a variety of applications.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.