B0505S-1WR3 Common troubleshooting and solutions

Understanding the B0505S-1WR3 and Common Troubleshooting Scenarios

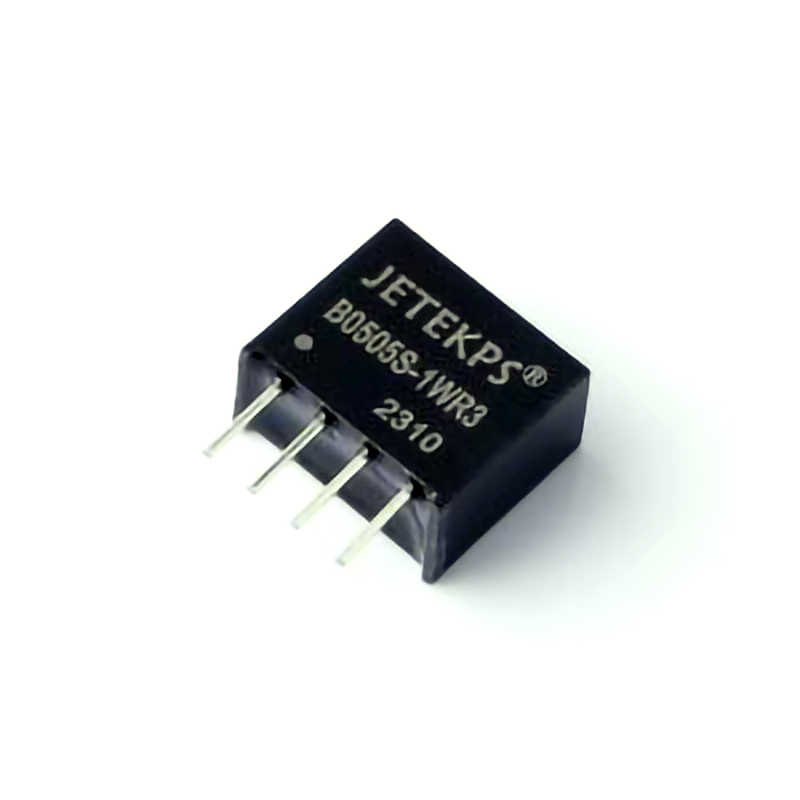

The B0505S-1WR3 is a compact, reliable DC-DC converter designed for a variety of electronic applications. Typically used in industrial, communication, and automation systems, this module is responsible for efficiently stepping down or stepping up input DC voltage to the required level for different components. However, like any electronic component, it can encounter issues that affect its performance. Identifying and resolving these issues promptly is crucial for maintaining system stability and ensuring uninterrupted operation.

1.1 Power Supply Issues

One of the most common problems with the B0505S-1WR3 converter is insufficient input voltage. For optimal performance, this converter requires an input voltage range of 4.5V to 5.5V. When the input voltage falls below the minimum threshold or spikes beyond the maximum, the converter will either fail to function or operate erratically.

Solution: Always verify the input voltage with a multimeter before installing the converter. If the input voltage is not within the specified range, consider adding a voltage regulator or replacing the power supply. Additionally, check for any loose connections or damaged wires that may cause voltage drops.

1.2 Overload or Short Circuit

Another common issue is when the B0505S-1WR3 is subjected to an overload or short circuit. This can happen if the output current exceeds the converter’s rated capacity (3W output power), or if there's a short in the connected load. Overloading can lead to overheating, excessive current draw, and eventually failure of the converter.

Solution: Ensure that the output load is within the converter’s specifications. Use a current limiter or fuse to prevent short circuits, and always check the wiring for possible short circuits before powering up the system. If necessary, opt for a converter with a higher power rating.

1.3 Output Voltage Instability

Another issue users might face is unstable or fluctuating output voltage. This can manifest as ripple or noise on the output voltage, causing improper operation of connected components.

Solution: Ripple and noise are often caused by poor filtering or grounding. Check the input and output capacitor s to ensure they are functioning correctly. Adding additional capacitance on the input and output might also help smooth out fluctuations. Additionally, ensure proper grounding of the converter, as poor grounding can exacerbate voltage instability.

1.4 Heat Dissipation Problems

The B0505S-1WR3 has built-in thermal protection, but it still requires adequate heat dissipation to prevent overheating, which can lead to premature failure. If the converter operates in an environment with high ambient temperatures or lacks proper ventilation, it might overheat and enter a protection mode.

Solution: Install the converter in a well-ventilated area, and consider adding a heatsink or fan to help with heat dissipation. Make sure that the converter is not located near heat sources and that the ambient temperature is within acceptable limits (up to 85°C for the B0505S-1WR3).

1.5 Improper Load Connection

Sometimes, the issue could be as simple as a faulty or improper load connection. If the converter’s output is not correctly connected to the load, the converter might not function as expected.

Solution: Verify that all load connections are secure and correctly wired according to the manufacturer's guidelines. Use a continuity tester to ensure there are no broken connections or faulty wiring.

Advanced Troubleshooting and Preventative Measures for B0505S-1WR3

While basic troubleshooting steps can resolve many issues, there are more advanced techniques and preventative measures that can be taken to ensure long-term reliability and minimize downtime.

2.1 Input Power Quality and Noise

A crucial aspect of DC-DC converter performance is the quality of the input power. If the input voltage is noisy or unstable, it will directly affect the output of the B0505S-1WR3. This is especially critical in sensitive applications where clean power is essential.

Solution: To reduce input power noise, you can add a filter capacitor or a ferrite bead at the input. These components help smooth out high-frequency noise and prevent it from reaching the converter. Additionally, ensure that the power supply is a stable source, free from spikes and transients that could damage the converter.

2.2 External EMI (Electromagnetic Interference)

DC-DC converters, like the B0505S-1WR3, can sometimes emit electromagnetic interference (EMI) that might affect nearby sensitive equipment. Conversely, external EMI sources can also disrupt the operation of the converter, leading to inefficiency and malfunctions.

Solution: Proper shielding is key in preventing EMI-related issues. Encase the converter in a metal enclosure to shield it from external interference. If the converter is emitting excessive EMI, adding ceramic capacitors at the input and output can help reduce the noise. Additionally, using ferrite beads and twisted pair cables for connections can minimize EMI propagation.

2.3 Overvoltage or Undervoltage Conditions

Overvoltage or undervoltage situations can also occur if there is a malfunction in the power supply system. The B0505S-1WR3 has built-in protection against overcurrent and overtemperature, but it does not have built-in overvoltage protection. If the input voltage exceeds the specified range, the converter could be permanently damaged.

Solution: Ensure that the input power supply has overvoltage protection in place. You can use a Zener diode or a crowbar circuit to prevent excessive voltage from reaching the converter. Installing a surge protector is also a good practice to protect against voltage spikes.

2.4 Diagnosing Using a Thermal Imager

For more complex troubleshooting, a thermal imager can be a valuable tool. By using a thermal camera, you can identify hotspots on the B0505S-1WR3 converter, which might indicate areas of excessive heat due to overloading or poor thermal management.

Solution: Use a thermal imager to check the temperature distribution on the converter’s surface. If you notice any hotspots, investigate the components in that area for possible failure. Overheating components may need to be replaced, and better thermal management solutions should be considered.

2.5 Comprehensive Load Testing

After resolving any potential issues, it is essential to test the converter under real-world load conditions. This step will help verify that the output voltage remains stable and the converter can handle the current demands of the load.

Solution: Use an electronic load tester to simulate the connected load and test the converter’s performance under varying conditions. Monitor the output voltage for fluctuations or instability, and ensure the converter operates within its specified parameters. If any irregularities occur, consider adjusting the input voltage or load configuration.

2.6 Regular Maintenance and Monitoring

To avoid future issues, regular maintenance and monitoring are essential. Power converters like the B0505S-1WR3 can last for years if properly maintained, but ignoring early signs of wear or stress can lead to failure at critical times.

Solution: Implement a regular inspection schedule to check the health of the converter. Look for signs of overheating, physical damage, or any issues with connections. Periodically test the converter’s output to ensure it remains stable and within specifications. Additionally, consider adding monitoring tools to continuously track the performance of the converter, especially in mission-critical applications.

Conclusion: Ensuring Long-Term Reliability

The B0505S-1WR3 is a robust and reliable DC-DC converter when used in the correct conditions, but like all electronic components, it requires attention to detail to ensure optimal performance. By understanding common troubleshooting scenarios and applying the right solutions, you can extend the lifespan of the converter and ensure your system operates smoothly.

Through careful monitoring, maintenance, and strategic upgrades, you can prevent issues before they arise and maximize the efficiency and reliability of your power systems. Troubleshooting is not just about solving problems—it’s about building a proactive approach to power management that ensures your systems continue to perform at their best.

This guide has covered the essential troubleshooting steps, as well as advanced techniques for ensuring the B0505S-1WR3 operates reliably. By applying these solutions, you can address common issues and minimize downtime, ultimately achieving a high level of system stability and performance.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.