MAX6675ISA+T Common troubleshooting and solutions

Understanding the MAX6675ISA+T and Common Troubleshooting Scenarios

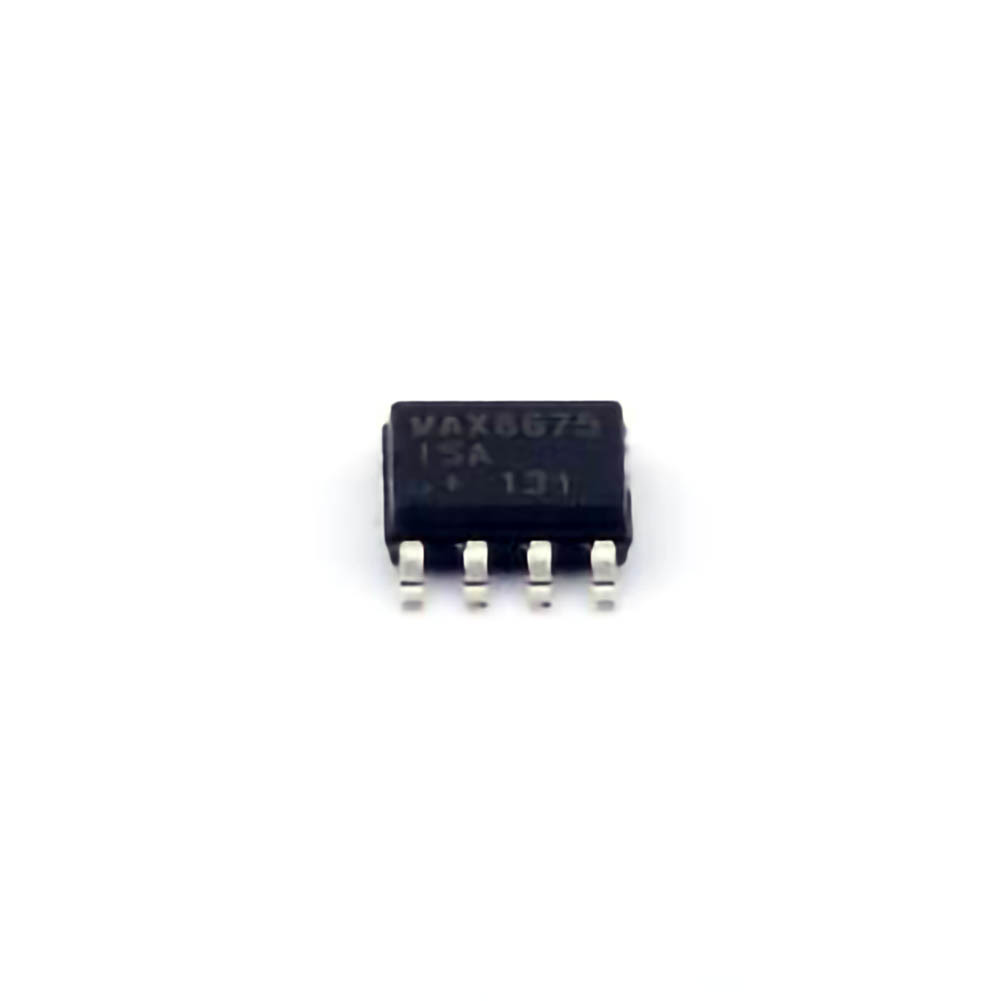

The MAX6675ISA+T is a popular digital thermocouple-to-digital converter, often used in temperature measurement applications. By interfacing directly with a K-type thermocouple, it allows users to easily measure temperatures over a wide range without requiring complex analog-to-digital conversion circuits. This makes it highly useful in industrial settings, DIY projects, and research applications. However, like all electronic devices, the MAX6675ISA+T is not immune to issues. In this article, we’ll explore common problems that can occur when using the MAX6675ISA+T and provide step-by-step troubleshooting solutions to resolve them.

What is the MAX6675ISA+T?

Before delving into troubleshooting, it’s essential to understand the basic functioning of the MAX6675ISA+T. It is a 12-bit, SPI-compatible, temperature-to-digital converter designed to interface with K-type thermocouples. It provides accurate temperature readings in the range of 0°C to 1024°C, making it ideal for various industrial and scientific applications. The MAX6675ISA+T operates by converting the analog signal from the thermocouple into a digital output that can be read by a microcontroller or processor.

While the Sensor is reliable, several factors can affect its accuracy and operation. Let’s review some of the most common issues and how to resolve them.

1. Incorrect Temperature Readings

One of the most common issues users face when working with the MAX6675ISA+T is incorrect or inaccurate temperature readings. There are several possible causes for this.

Possible Causes:

Faulty Thermocouple: A malfunctioning or damaged thermocouple is the most common reason for incorrect readings. K-type thermocouples are highly sensitive and prone to degradation due to excessive heat or mechanical stress.

Poor Connections: Loose or poor-quality connections between the thermocouple and the MAX6675ISA+T module can lead to inaccurate readings.

Improper Calibration: If the MAX6675ISA+T is not properly calibrated, the temperature readings may not be accurate. Calibration is especially important when the sensor is used in specialized applications requiring precise measurements.

Interference: Electrical noise or signal interference from nearby equipment can cause fluctuating or erroneous temperature readings.

Solutions:

Inspect the Thermocouple: Check the thermocouple for any signs of wear or damage. Replace it if necessary.

Check Wiring and Connections: Ensure all wires are securely connected and that there are no shorts or breaks in the wiring. Use high-quality connectors and wires for improved reliability.

Calibrate the Sensor: Follow the manufacturer’s guidelines for calibration to ensure accurate temperature readings. In some cases, using a known temperature reference (e.g., a calibrated thermometer) can help in this process.

Minimize Interference: Ensure that the MAX6675ISA+T is not placed near high-voltage or high-frequency sources that might cause electrical interference. Proper grounding and shielding can help reduce noise.

2. SPI Communication Failure

The MAX6675ISA+T communicates via the SPI protocol, which involves several key pins: SCK (clock), CS (chip select), MISO (Master In Slave Out), and VCC (voltage supply). Problems in SPI communication can prevent the sensor from transmitting data, leading to failure in obtaining temperature readings.

Possible Causes:

Incorrect Wiring: If the wiring between the MAX6675ISA+T and the microcontroller is incorrect, the SPI communication may fail.

Faulty SPI Settings: The MAX6675ISA+T requires specific SPI settings, including the correct clock polarity and phase. Incorrect settings in the microcontroller or processor may cause data to be transmitted incorrectly.

Power Issues: Inadequate power supply to the MAX6675ISA+T can disrupt its communication with the microcontroller, causing read errors or failure to send data.

Solutions:

Verify Connections: Double-check that the connections between the MAX6675ISA+T and the microcontroller are correct. Ensure that the SCK, CS, MISO, and VCC pins are connected properly.

Check SPI Settings: Ensure that the SPI settings (clock polarity, phase, and speed) in the microcontroller match the requirements of the MAX6675ISA+T. Typically, the clock polarity should be set to "0", and the clock phase should be "1".

Inspect Power Supply: Make sure that the MAX6675ISA+T is receiving a stable 3.3V or 5V power supply, depending on the version you are using. Voltage fluctuations or inadequate power can cause communication errors.

3. Module Not Powered On

Another common issue is the MAX6675ISA+T module not powering up. If the sensor is not powered, it won’t be able to provide temperature readings.

Possible Causes:

Incorrect Power Supply: Providing an incorrect voltage to the MAX6675ISA+T can prevent it from powering up.

Power Supply Wiring Issues: A loose or faulty connection between the power supply and the MAX6675ISA+T could result in no power being supplied to the module.

Damaged Module: In some cases, the module itself may be damaged and may not power up even when the wiring is correct.

Solutions:

Check the Power Supply Voltage: Ensure that the MAX6675ISA+T is powered with the correct voltage (typically 3.3V or 5V). Double-check the voltage specifications and ensure compatibility with your system.

Inspect Power Connections: Make sure that the power supply pins (VCC and GND) are properly connected and there is no loose wiring.

Test with a Different Module: If the power supply and connections appear correct but the module still does not power up, try replacing the MAX6675ISA+T with a new one to check if the module is damaged.

4. Inconsistent or Fluctuating Readings

In some cases, the temperature readings may fluctuate unpredictably, even when the system is properly set up. This issue can often be traced to several key factors.

Possible Causes:

Thermocouple Interference: If the thermocouple is exposed to fluctuating environmental conditions (e.g., drafts or sudden temperature changes), the readings may be inconsistent.

Poor Grounding: Inadequate grounding or the presence of ground loops can cause unstable readings.

High Noise Levels: High electrical noise from nearby components, such as motors, power supplies, or other devices, can lead to fluctuating readings.

Solutions:

Ensure Stable Environmental Conditions: Ensure that the thermocouple is placed in a stable environment where temperature fluctuations are minimal.

Improve Grounding: Use proper grounding techniques, such as a dedicated ground plane, to reduce noise and ensure stable readings.

Use Shielded Cables: If electrical interference is suspected, consider using shielded cables for the thermocouple and sensor to reduce noise.

Advanced Troubleshooting and Maintenance Tips for the MAX6675ISA+T

In this section, we will dive deeper into advanced troubleshooting techniques and maintenance tips for the MAX6675ISA+T to ensure optimal operation over the long term. These strategies will address some of the more complex issues that users might face when using the device in challenging conditions or with demanding applications.

1. Handling Long Cable Lengths for the Thermocouple

When using the MAX6675ISA+T, you might need to work with long thermocouple cables, especially in industrial or large-scale applications. Long cables can introduce additional Resistance , which can affect the accuracy of temperature readings.

Possible Causes:

Thermocouple Wire Resistance: The resistance of the thermocouple wires can change with the length of the cable. This can result in inaccurate readings, especially over long distances.

Signal Loss: Long cables can also cause signal degradation due to electromagnetic interference and the inherent resistance of the wires.

Solutions:

Use Proper Cable Gauge: Use high-quality, low-resistance wires and the appropriate gauge for long cable runs. For best results, use wires with minimal resistance and ensure that they are designed for thermocouple applications.

Minimize Cable Length: Where possible, minimize the length of the thermocouple cables or use signal amplifiers to maintain the integrity of the data.

Use Cold-Junction Compensation: The MAX6675ISA+T includes cold-junction compensation to help correct for any errors due to the measurement of ambient temperature at the connection points. Ensure that the sensor is configured correctly to utilize this feature.

2. Working with Multiple Sensors

In some applications, you might want to use multiple MAX6675ISA+T modules to measure temperature at different points. However, connecting multiple modules to a single microcontroller can sometimes lead to conflicts or issues in reading data from each module.

Possible Causes:

SPI Bus Conflicts: When using multiple MAX6675ISA+T modules, there may be conflicts on the SPI bus, particularly if the chip select (CS) pins are not properly configured.

Timing Issues: If the timing or clocking for the SPI bus is incorrect, data may be corrupted or not transmitted from the sensors.

Solutions:

Use Separate CS Pins: Ensure that each MAX6675ISA+T module has its own dedicated chip select (CS) pin. This will prevent conflicts when selecting which sensor to read from.

Adjust Timing: Verify that the SPI clock speed and timing are configured appropriately for multiple devices. You may need to introduce small delays between reads to ensure that data is not overwritten.

3. Maintaining Long-Term Reliability

Finally, it’s important to consider the long-term reliability of the MAX6675ISA+T, especially in industrial environments where the sensor may be exposed to harsh conditions.

Possible Causes:

Thermal Stress: Over time, high thermal stresses from frequent temperature changes can cause degradation of components.

Dust and Debris: Exposure to dust and debris can interfere with sensor connections and affect sensor accuracy.

Solutions:

Proper Enclosures: Use enclosures or protective cases to shield the MAX6675ISA+T and thermocouple from environmental factors like dust, moisture, and physical damage.

Regular Calibration and Testing: Periodically test and calibrate the sensor to ensure that it remains accurate over time. Regular maintenance can help catch any issues early before they affect system performance.

By understanding and addressing these common issues, you can ensure that your MAX6675ISA+T operates reliably and accurately, helping you achieve the best results in your temperature measurement applications. With the right troubleshooting and maintenance practices, you can maximize the lifespan and performance of your sensor, ensuring it continues to meet your needs effectively.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.